The Complete Guide to Brick Masonry: Techniques, Wall Types, Repairs, and Commercial Services

Brick masonry blends long-lasting strength with timeless curb appeal, which is why builders and property owners choose it for homes and commercial projects alike. In this guide we cover the core techniques, the main wall types, the tools you’ll need, common repairs, and the real advantages of brick in Oklahoma City. You’ll find clear steps for site prep, mortar mixing, and material selection — plus practical cost factors to budget for. If you need help, ACME Construction offers local expertise to bring your masonry project to life. Read on and you’ll finish this guide with a confident plan for your brick veneer panels.

Fundamental Bricklaying Techniques for Building Long-Lasting Walls

Good brickwork starts with reliable techniques: thorough site preparation, properly mixed and applied mortar, and consistent brick laying. Each step affects the wall’s strength and lifespan, so following best practices pays off in durability and appearance.

How to Prepare a Site for Bricklaying

Site preparation sets the stage for successful masonry. Key tasks include:

- Clear the Area: Remove debris, vegetation, and any old structures that would interfere with new work.

- Establish Levels: Use string lines, batter boards, and spirit levels to create a true, even base for the brickwork.

- Plan Drainage: Protect the wall from standing water with proper grading, footing drains, and damp-proofing where needed.

Careful prep creates a stable foundation and reduces issues later in the build or during the life of the wall.

Steps for Mixing and Applying Mortar Correctly

Mortar quality makes a big difference in bond and durability. Follow these steps:

- Choose the Right Mortar: Match mortar type to the job — for example, Type N works well for general exterior walls, while Type S is better for higher-strength or load-bearing work.

- Use Proper Mixing Ratios: A common workable mix is 1 part cement, 1/2 to 1 part lime, and 4 to 6 parts sand — adjust for local materials and conditions.

- Apply Evenly: Butter the bricks and bed the joints with a trowel so mortar fully contacts both units; consistent joint tooling improves weather resistance and appearance.

Well-prepared mortar and consistent application contribute directly to a longer-lasting masonry assembly.

Research shows mortar composition — particularly the binder-to-aggregate ratio — strongly influences repair mortar strength and compatibility with existing masonry.

Binder/Aggregate Ratio in Repair Mortars

A study evaluated repair mortars with varying binder-to-aggregate (B/Ag) ratios to see how limestone aggregate affects mortar properties and compatibility with porous natural stone. Three mortar types with different aggregate contents were tested using mercury intrusion porosimetry (MIP) and water saturation methods to compare pore structure and strength.

The influence of binder/aggregate ratio on the pore properties and strength of repair mortars, Á Török, 2013

Which Types of Brick Walls Are Commonly Used on Projects?

Builders use several brick wall systems depending on performance needs and budget. Knowing the differences helps you select the right approach for your project.

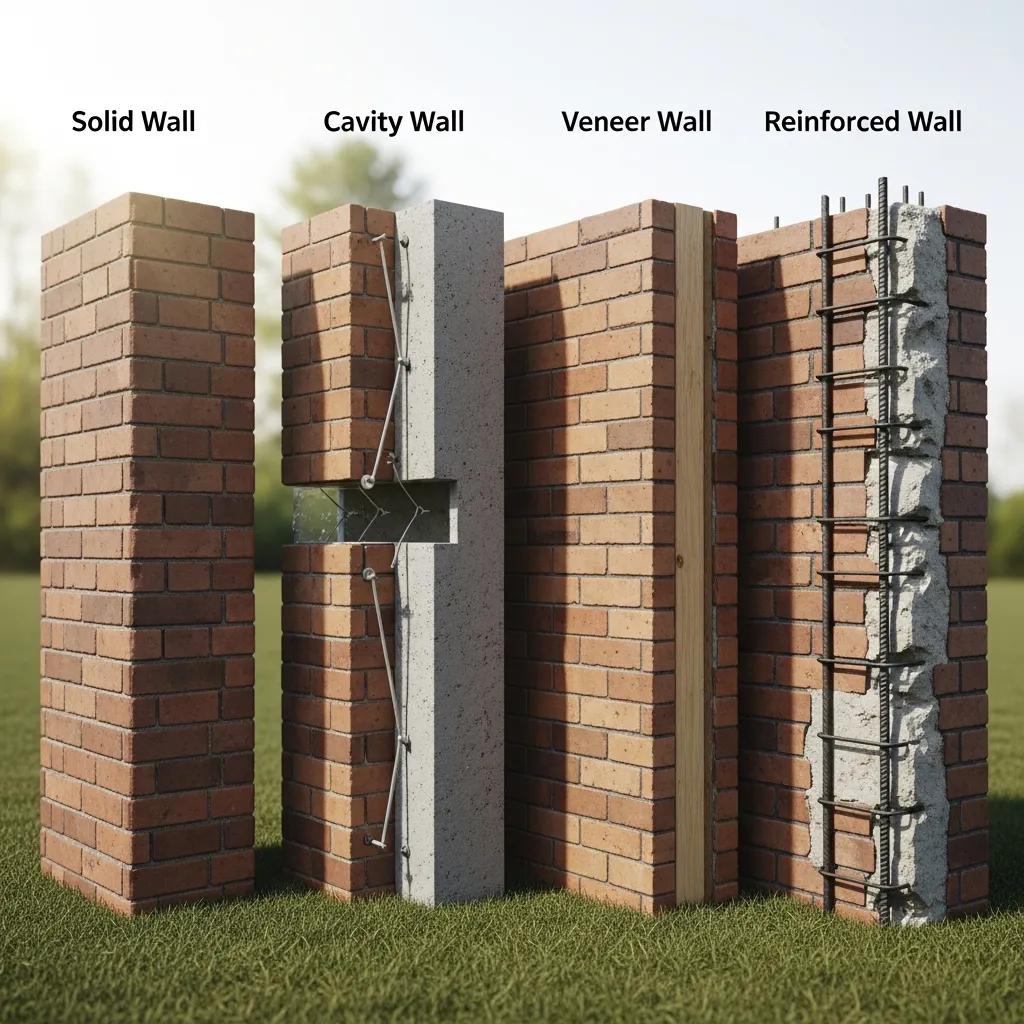

Characteristics of Solid, Cavity, Veneer, and Reinforced Brick Walls

Common wall types include:

- Solid Brick Walls: Built entirely of brick, these give strong load-bearing capacity and good thermal mass.

- Cavity Walls: Two brick leaves with a gap between them — the cavity improves insulation and keeps moisture from passing through.

- Veneer Walls: A single brick facing attached to a framed structure for the look of brick without the full mass of a solid wall.

- Reinforced Brick Masonry: Brickwork combined with steel reinforcement to handle higher loads and improve seismic performance.

Each system has trade-offs in cost, insulation, and structural behavior — choose the one that fits your site and specs.

Tests show reinforced masonry panels can achieve good ductility and seismic resistance when horizontal steel and confined compression zones are properly designed into the wall.

Seismic Performance of Reinforced Brick Masonry Walls

This paper summarizes results from racking tests on 18 reinforced masonry wall panels, including both RBM and hollow-cell systems under slow cyclic loading. The findings indicate acceptable ductility when adequate horizontal steel carries shear and compression zones at wall corners are confined using thin reinforcing plates in the bottom mortar courses.

Seismic resistance of brick masonry walls, 1974

How Brick Bond Patterns Influence Strength and Look

Bond pattern affects both structure and style. Common patterns are:

- Running Bond: Stretcher courses offset by half a brick — a durable, widely used pattern.

- Stack Bond: Bricks stacked directly above each other for a modern appearance; typically requires reinforcement or grout for load-bearing use.

- Flemish Bond: Alternating headers and stretchers in each course for a decorative, traditional look with solid performance.

Pick the bond that balances the visual you want with the structural needs of the wall.

Essential Tools and Materials for Quality Brick Masonry

Having the right materials and tools makes brickwork faster and more reliable. Below are selection guidelines and the key tools professionals use.

Selecting Bricks and Mortar for Your Project

Consider these points when choosing materials:

- Material Performance: Use bricks that meet local code and suit Oklahoma’s climate — frost resistance and low absorption matter in freeze-thaw conditions.

- Project Needs: Match the brick size, face finish, and mortar strength to the structural and aesthetic goals of the build.

- Budget vs. Value: Balance upfront material cost with lifespan and maintenance needs to find the best long-term value.

Picking the right materials up front reduces surprises and repair work down the line.

Key Masonry Tools Professionals Rely On

Pros keep these tools close at hand:

- Trowels: For spreading and tooling mortar accurately.

- Spirit Levels and Line Levels: To keep courses plumb and level across long runs.

- Mason’s Lines and Blocks: For straight, true walls and consistent course heights.

Correct tools and tidy setup lead directly to better-looking, longer-lasting brickwork.

How Brick Masonry Repair Restores Strength and Appearance

Timely repair keeps masonry performing and prevents small issues from becoming big, expensive problems. Below are the common problems and how they’re addressed.

Common Brick Damage and How to Spot It

Watch for these signs of masonry distress:

- Cracks: From settlement, movement, or thermal stress — monitor for growth and pattern to diagnose the cause.

- Spalling: Brick faces flaking or shedding, usually from moisture penetration and freeze-thaw cycles.

- Discoloration: Stains or efflorescence from water or salts that can indicate moisture issues.

Early detection allows targeted repairs, protecting the structure and saving money long-term.

How Tuckpointing and Brick Replacement Repair Walls

Two standard repair methods are:

- Tuckpointing / Repointing: Remove deteriorated mortar and replace it with a compatible mix to restore bond and appearance while keeping the original bricks intact.

- Brick Replacement: Remove and replace individual damaged bricks when units are cracked or badly spalled, matching mortar and tooling for a seamless repair.

Proper repointing is about matching mortar composition and joint technique; when done correctly it preserves both strength and the historic character of masonry work.

Repointing Techniques for Historic Brick Masonry

Repointing — sometimes called tuckpointing — involves removing failing mortar from masonry joints and installing new mortar. Success depends on choosing a compatible mortar and replicating the original joint finishing techniques to protect the bricks and retain the wall’s performance.

Repointing mortar joints in historic brick buildings, 1977

Both approaches extend the life of brickwork and keep structures functioning as intended.

Benefits and Typical Cost Factors for Brick Masonry in Oklahoma City

Brick offers many advantages, and understanding common cost drivers helps you plan a realistic budget for residential or commercial work.

Why Brick Wins for Durability, Energy Efficiency, and Low Upkeep

Brick is valued for:

- Durability: Resistant to pests and weather, brick stands up well over decades with minimal intervention.

- Energy Performance: The thermal mass of brick helps even out indoor temperature swings, reducing heating and cooling load.

- Low Maintenance: Properly built brickwork needs less frequent upkeep than many other cladding systems.

These benefits make brick a smart long-term investment for many property types.

Common Material and Labor Costs for Brick Projects

Costs vary by scope, but typical ranges include:

| Cost Factor | Description | Average Cost |

|---|---|---|

| Material Costs | Price of bricks and mortar | $6 – $15 per square foot |

| Labor Costs | Skilled mason wages | $40 – $75 per hour |

| Project Complexity | Additional costs for intricate designs | Varies significantly |

Use these figures as a planning guide — site conditions, design detail, and access can change final pricing. A local contractor like ACME can provide a tailored estimate for your project.

How ACME Construction Delivers Commercial Brick Masonry in Oklahoma City

ACME Construction specializes in brickwork for both commercial and residential projects across Oklahoma City. We combine experienced crews with practical planning to deliver durable masonry that meets your schedule and budget.

What Sets ACME Construction’s Expertise and Service Apart?

We focus on:

- Proven Experience: Our masons bring years of field experience on a wide range of projects.

- Client-First Service: Clear communication, reliable timelines, and quality workmanship are standard on every job.

- Portfolio of Success: Completed projects and satisfied clients demonstrate our ability to meet design and performance goals.

That combination makes ACME a dependable partner for masonry work in the region.

How to Request a Free Quote or Consultation

Getting started is simple. When you contact ACME Construction for a free consultation, please share:

- Project Scope: A brief description of the work you need.

- Timeline: Your preferred start or completion dates.

- Budget: Any budget range you’re working with.

We’ll review your details and follow up with a clear estimate and next steps so you can move forward with confidence.

Frequently Asked Questions

What are the environmental benefits of using brick in construction?

Brick is made from natural clay and has a long service life, which reduces the need for replacement and waste. Its thermal mass helps stabilize indoor temperatures, lowering energy use for heating and cooling. Many bricks can also be reused or recycled, so choosing brick supports more sustainable building choices over time.

How does weather affect brick masonry construction?

Weather affects mortar curing and workability: cold slows curing, extreme heat speeds drying and risks shrinkage cracks, and rain can compromise fresh mortar and finished joints. Good practice is to plan around forecasts, use weather protection when needed, and adjust mortar mixes for temperature to ensure a durable result.

What maintenance practices are recommended for brick masonry?

Regular visual inspections are the first line of defense—look for cracks, spalling, or mortar loss. Clean gently with a soft brush and mild detergent when needed, and address moisture sources that could cause damage. Repointing deteriorated joints and replacing badly damaged bricks will preserve the wall’s integrity.

Can brick masonry be used in seismic-prone areas?

Yes — but design matters. Reinforced brick masonry that incorporates properly placed steel and confinement detailing can improve seismic performance. Follow local codes and consult a structural engineer to specify reinforcement and connection details appropriate for seismic loads.

What are the differences between traditional and modern brick masonry techniques?

Traditional masonry emphasizes hand craftsmanship and detailing, while modern methods may use pre-mixed mortars, power tools, and engineered reinforcement to speed work and meet stricter structural needs. Both approaches are valid; the choice depends on aesthetic goals, schedule, and structural requirements.

How can I ensure the longevity of my brick masonry structure?

Longevity starts with good design and materials — proper site prep, compatible mortar, and quality bricks suited to the climate. Maintain consistent drainage, inspect regularly, and address repairs promptly. Following these practices will maximize the lifespan of your masonry investment.